SeKON SmI

SePPS Industry is a Software Complete-Solution for automatic manufacturing of Stone Countertops or slabs material.

SePPS Industry aimed at medium and large businesses who want to manufacture their products planned, reproducible and automatically.

The program is modular in order to meet the various demands in this industry. It includes the following components:

- Slab Management

- Photo-Capturing

- Inventory

- Nesting in TOP

- Production Controling for cuts

On this page we want to give you a short introduction of all processing stations.

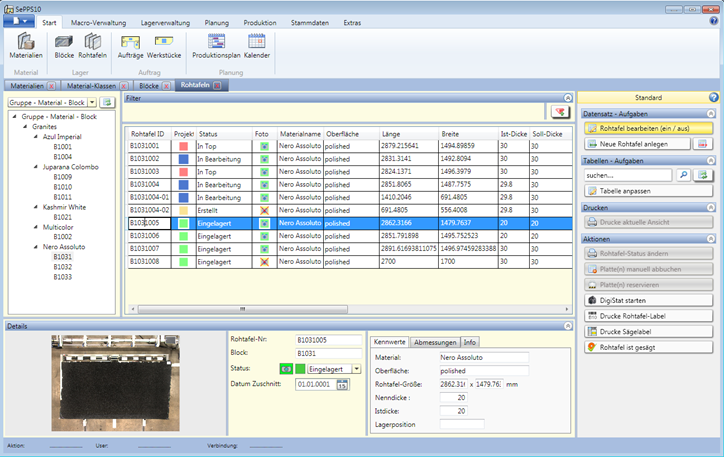

Slab Management

For all orders you need – of course – slabs. For this reason SePPS contains a specially for Stone Industries developed slabs administration. Like an order, slabs will be handled in SePPS as well.

SePPS contains all information for slabs:

- Interface to ERP

- Interface to slab digitizing

- Associated blocks

- Stock value per date

- Label Printing

- Managing of vectorised photos

- Return of usage and waste statistics to ERP

- Classification

- Storage (place)

Photo-Capturing

In addition to the slab data, slabs can be photographed and vectorized via DigiStat if required. A PDA (Production Data Acquisition) mask specially developed for this application makes work easier for the operator and reduces the possibility of errors.

Afterwards, the slabs can then be classified, labeled and stored depending on its condition.

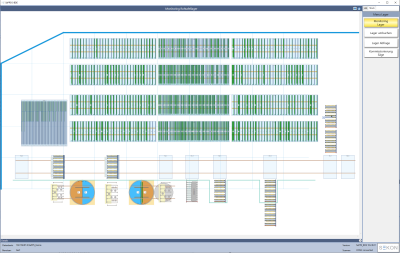

Warehouse Management

Stocking Slabs is handled by the Stock Management Slabs are now sorted for quick access in the production:

- Lists with free definable racks (A-Frames, L-Frames, Palettes etc.)

- Lists for stock positions and stations for racks

- Rebooking of positions for Slabs over userfriendly BDE-masks

- Request of slabs, racks and positions

- Communikation to High Storage Systems

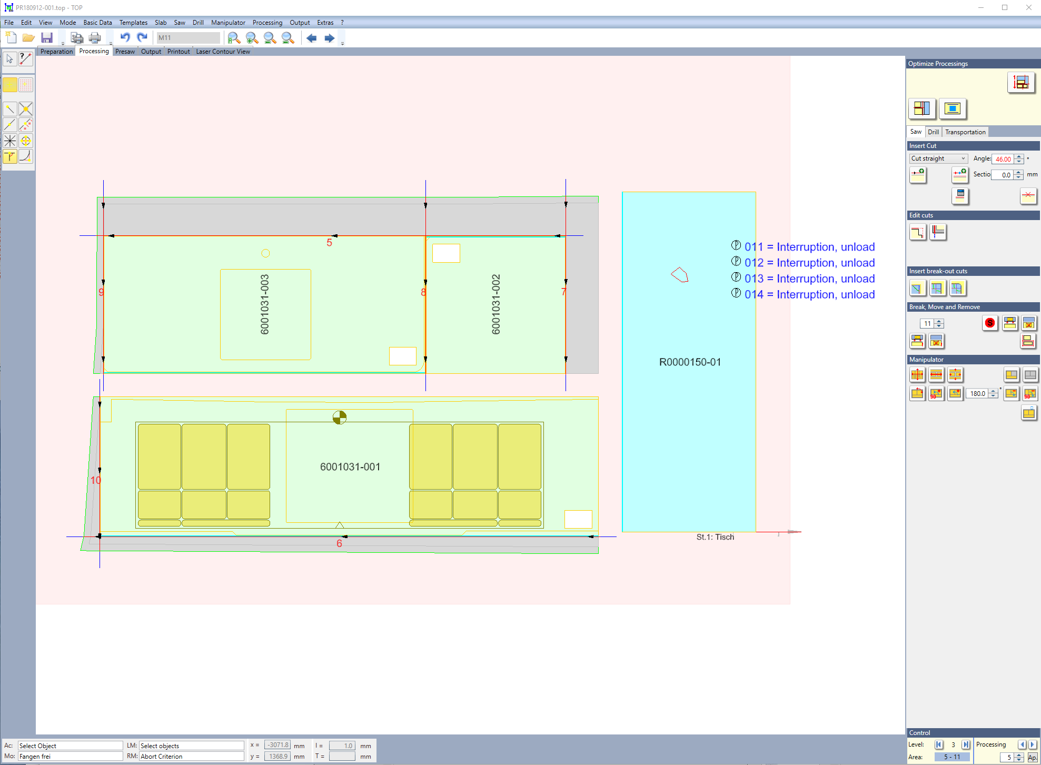

Nesting Slabs

Through TOP it is possible to manage and organize different orders to slabs. In this way it is possible to know - before cutting - how many slabs you will need.

- Easy arranging and nesting of workpieces in the office

- Uniform menu-layout for all type of machines

- Modules for further functions (Manipulator, Drilling, Milling, Waterjet, Unloading)

- Connection to SePPS Database

- Feedback and Return of Remnants

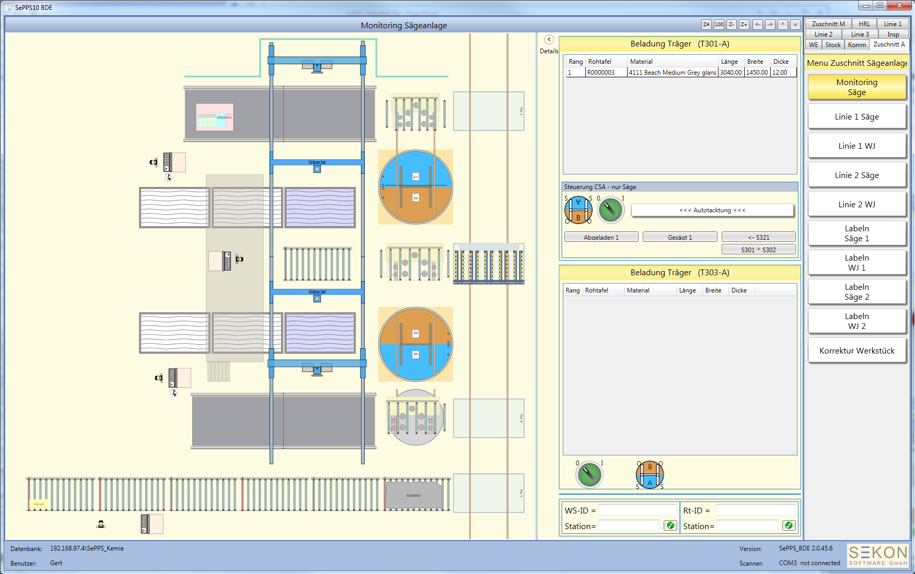

Sawing

The production itself starts with the commissioning of all the required slabs.

The BDE-Dialog shows all slabs to the operator, all slabs he must provide in his shift or for the day.

Through in top nested slabs and the produce date the list will be automatically filled.

Remnants get automatically the status „accessible“ for further nesting in top.

Saws can get slabs manual or automatically loaded. (NC-Programs included)

The operator can – if needed - modify a NC-Program

After Sawing all parts get the status „SAWED“

After Sawing all parts get a label